What is Metal roof restoration?

Metal roof restoration is defined in a variety of ways by a number of varying opinions. However, in most cases, it can be defined as: 1) a full scope repair, reseal and/or replacement of defective roof system components, 2) re-establishing weather-tight seals at flanges, laps, joints, closures, fasteners, etc. and 3) the cleaning, priming and application of a protective industrial coating to a metal panel substrate or metal panel substrate that has a previously applied coating. The primary purpose of Metal roof restoration, in most cases, is to preserve and sustain the integrity of the metal panel substrate and ancillary components for extended longevity and the elimination of moisture infiltration. The restoration process will bring a metal roof system back to a level of maintainability, and usually includes: a 10 year manufacturer material warranty and a 10 year contractor labor and leak-proof guarantee.

What wears a roof out:

- Exposure – either long term exposure to the elements or shorter term exposure to damaging air pollutants and chemicals

- Structural movement – Such as building settlement or expansion / contraction not accommodated by the roofing system

- Biological growth – Such as vegetation in areas of standing water or algae

- Not fixing problems promptly – These can add up to a much shorter roof life – e.g., if a small problem is not repaired, then a large amount of insulation can be damaged

- Forgetting about maintenance – This is perhaps the single biggest cause of premature roof failure

- Change in the use of the building – e.g., an increase in the interior relativity of a building can cause severe condensation problems within the roofing system

By Dick Fricklas * RSI contributing editor * 2/15/2006 * “Problem prevention is your best value”

Insidious and hidden deterioration beneath the surface caused by:

- Excess infiltration or exfiltration of air flow in the building envelope

- Moisture / condensation between roof panels and vapor barriers

- Excessive applications of non-compatible roof repair materials

- Mechanical / electrical / HVAC trade induced roof damage

- Thermal induced component stress & subsequent loss of fastener pre-load

NRRR engineer * 10/15/2013 * “Monitor and Maintain your roof system”

Considerations:

- Protective, industrial roof coatings do not stop leaks

- 99% of water infiltration problems emanate at panel to panel lap & joint seals, at roof system component sealing details (such as caps , closures and flashing to name a few) and fasteners / lok-rivets.

- If a significant portion of your metal roof panels are perforated, due to rust through, the roof will need to be replaced or retro-fitted.

- Galvalume metal roof panel life spans are typically two to three times those of single ply membrane systems, and they can outlive the useful life of a building if they are properly maintained.

- Routine / annual metal roof inspections, when integrated into a proactive, preventive maintenance and repair curriculum, can extend the life of a galvalume roof for many decades without a coating application.

- Once you start down the path of a roof coating application you cannot turn back.

- Metal roof restoration with coating application has its place, and is very cost effective when compared to re-roofing or retro-fit roofing installations. However, if modest preventive maintenance and repair activities can be used to eliminate moisture infiltration, a roof coating application is not required.

- Excessive amounts of repair material, applied at exterior roof component locations that are subject to ponding water, can become an owner’s nightmare and precipitate premature roof replacement. “More is not always better”.

Most commonly used rationale and purpose for Metal roof restoration?

- Metal roof panels have commenced base steel substrate oxidation – reduction process; whether due to age & weathering, atmospheric exposure to harmful elements and/or extensive failures at panel laps & joints or panel – component interfaces due to applications of non-conforming/non-compatible repair materials.

What a Metal roof restoration coating application will do:

- Will preserve and protect the base substrate metal panel material

- Will extend metal roof panel longevity

- Will reduce metal roof system thermally induced movement

- Will reduce metal roof system panel and component stresses and point loads

- Will enhance energy conservation (depending on type application and geographical location)

What a Metal roof restoration coating application will not do:

- Will not stop roof leaks

- Will not always enhance energy conservation (depending on type application and geographical location) [insert article(s)]

- Will not eliminate condensation issues

- Will not correct surplus/deficient building air flow CFM (i.e. excessive ΔP problems)

National Roof coating application guidelines:

National Roof employs restoration processes and procedures that meet or exceed:

- Metal roof manufacturer original installation details where applicable

- Industry standards,

- Division 7 guidelines,

- Applicable code requirements

- Manufacturer coating application specifications in concert with enhanced repair techniques acquired over many decades in the restoration business.

Quotes from Roofing Professionals, Consultants and Researchers

“Roughly two-thirds of commercial roof activity today consists of re-covering or re-roofing existing buildings.”

Richard Fricklas – 9/10/2012

“North American market for Commercial Roofing Materials to be worth about $6 billion dollars in 2014, not including installation”

Commercial Roofing Market Survey - 2013

"Estimates are that North American Low Slope Roofing Market exceeded 3 billion sq.ft. of re-roofing in the commercial arena”

Roofing Industry Consensus Data

“Except for structural errors, about 90% of all building construction problems are associated with water in some way"

(ASTM, 1982)

“Moisture in low-slope roofing is a multibillion dollar problem for the U.S. Roofing industry. It is estimated that energy losses through roofs in the U.S. are increased by 70% because of the loss of insulation’s thermal resistance due to moisture contamination.”

Andre’ O. Desjarlais – ORNL – Thermal Envelopes

“Moisture intrusion is the major reason why low-slope roofing systems fail prematurely.”

Andre’ O. Desjarlais – ORNL – Thermal Envelopes

“Buildings account for 40 percent of our nation’s energy consumption and almost 75 percent of the electricity used in the country”

- 9/12/2013 Roofing Contractor magazine

“Moisture accumulation in roof systems can create a number of costly problems, including dripping, accelerated insulation and membrane/substrate failure, the threat of roof structural deterioration, depreciation of assets and poor thermal performance. Moisture accumulation can severely impact the thermal performance of insulation in a roof system.”

Nan Byars – University of North Carolina @ Charlotte - 4th International Symposium on Roofing Technology

“COOL” Metal Roof Restoration:

Challenging What's Cool Is the exponential growth of cool roofing an impending catastrophe?

While most all roofing and energy conservation organizations are praising the benefits of white reflective, field applied, industrial roof coatings there are now concerns surfacing that require thoughtful consideration about potential drawbacks in certain situations. Read entire article

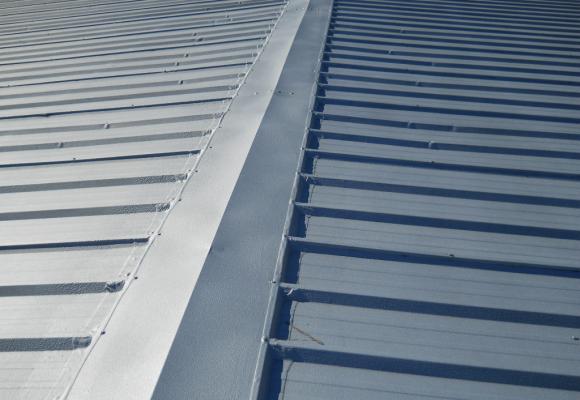

National Roof definition of a Full Metal Roof Restoration:

- Repair and/or replacement of defective / deficient: roof component flashing materials (i.e. rake flashing, step flashing, wall flashing, pipe / vent & stack flashing, transition flashing, etc.). Repair normally includes component resealing & refastening.

- Repair / replacement of defective / deficient: roof curbs, panel horizontal end & vertical side laps, expansion joints, eave lines & profile closures, ridge cap & profile closures, etc.). Repair normally includes component resealing & refastening.

- Repair / replacement of defective / deficient: field fasteners and suspect panel areas.

- High pressure cleaning of entire roof system, application of red zinc primer to heavily rusted areas, and the application of an industrial and protective coating over the subject metal roof system.

- Provision for a ten (10) year material & workmanship warranty and a ten (10) year leak-proof guarantee.

View Roof Restoration Applications Brochure

Metal Roof Restoration is a very extensive & intensive repair and coating application process that competes with the retro-fit and re-roofing systems. The restoration process is typically about a half to a third the cost of installing single ply or new metal roofing over an existing metal roof system, and is about 90% lighter than retro-fit roofing.

The most expensive material component in the Metal Roof Restoration process is the application of an industrial, premium grade, protective coating. The labor intensive repair / replacement details can run as high as the coating material cost if the roof system is sufficiently complex in: roof type & configuration, component profiles and number of penetrations.

National Roof also performs Roof Restoration on Commercial Single Ply Membranes such as EPDM & TPO

Commercial applications of single ply membranes have been successfully installed for many decades and are of great service for specific applications. However, single ply membrane roofing such as EPDM (black rubber) and TPO (Thermolplastic Poly-Olefin) systems have a significantly shorter life span than Galvalume metal roofing. As EPDM ages it loses elasticity and begins to shrink. This condition elevates stresses at field seams and detail flashing that will eventually result in failure at these weakest points. The good news is that EPDM roofing systems can be restored and protected with the application of premium, white reflective, elastomeric coatings for a prolonged life.

“Weathering of EPDM can cause changes in tensile strength and elongation properties of the rubber membrane. Generally, as the processing oils leach out, the membrane becomes less elastic, but stronger. This leaching phenomenon is evidenced by loss of membrane thickness and dimensional shrinkage. The elongation increases tensile strength and generally makes the EPDM less flexible. Puncture resistance and tear resistance will be reduced as the EPDM membrane loses its elasticity.”

Elastomeric Acrylic Roof Coatings for EPDM Roofing article – Joseph M. Rokowski & Thomas Ennis

read entire Elastomeric Acrylic Roof Coatings for EPDM article

TPO roofing systems are typically manufactured with impregnated reinforcing scrim. As the TPO ages the top protective layer eventually degrades and exposes the scrim. This condition is also prevalent at the heat welded field seam edges and at flashings. Existence of this physical state enables the wicking of moisture into the roofing system and accelerates degradation. The application of a protective elastomeric roof coating to TPO systems prior to significant deterioration will provide a waterproof barrier over the membrane & any exposed scrim and will extend the life of the TPO system for many more years of functional life; at a much lower cost than replacement.

National Roof partners with Karnak and Uniflex roof coating manufacturers and uses their proven, premium grade elastomeric coatings to perform single ply roof restorations. Both Karnak and Uniflex have been producers of; and innovators in; new technologies for enhanced elastomeric coatings applications. Both manufacturers have been leaders in the commercial coating industry for more than eighty years and are well recognized for their superior products. National Roof has been applying protective roof coatings from these manufacturers for a number of decades with great success. Let National Roof evaluate your system today.

read “A Practical Guide to White Coatings”

read “Karnak Coating Project Highlight

National Roof has observed over many years that there are only 4 or 5 primary reasons for a customer to consider a full metal roof restoration or why it makes sense:

- To protect a weathered base metal panel substrate, that is transitioning from normal surface oxidation to a phase of red oxide migration, from further degradation and deterioration. Although galvalume metal roof panels bring a superior, long lasting roof covering to most commercial buildings, they can experience a shorter than expected life span when exposed to corrosive environments or are neglected for extended periods of time.

- To re-apply a protective coating over a previously coated metal roof system that has been inspected, evaluated and qualified for an additional application.

- To reduce metal roof system movement (i.e. thermal induced expansion and contraction) with the use of highly reflective, cool roof coatings. This reduces fastener point loads and component stresses throughout the roof system.

- To gain advantages in energy conservation, monetary savings, LEEDS certification, and overall positive impact on the environment.

- Aesthetics

All of the previously mentioned reasons for considering metal roof restoration have their place. However, due to the wide variety of cold applied metal roof coatings available on the market, of varying quality and performance, it is crucial, if not mandatory, to gain an understanding of the realistic outcomes; both positive results as well as potential negative ramifications, before making a final decision. Roof surface preparation is the KEY to an exceptional and well adhered application.

Metal roof coatings: (“Don’t leap before you look”) – Doing a little bit of research on protective metal roof coatings can save major headaches down the road. Let National Roof assist you in evaluating your roof system today.